Institutional Biogas Plant – CHAROTTAR AGRO PRODUCE & PROCESSING (OPC) PVT. LTD. (CAPPL) (Vill: Ramnagar (Mogar), Tal: & Dist.: Anand)

| ||

Installed Biogas Plant Capacity | : | 45 CMD |

Raw Material Type | : | Mixed Waste (Cow Dung + Kitchen Waste) |

Feed Material Required | : | 1150 Kgs/day |

Biogas Utilisation Points | : | 9 nos. connections (Canteen & Staff Quarters) |

Total Project Cost | : | Rs.19.45 Lacs |

Financial Out lay Support | : | Rs. 6.05 Lacs (Subsidy from GEDA, Gandhinagar) |

Plant Commissioned On | : | 22nd SEPT’ 2022 |

Plant O&M By | : | CAPPL, Mogar |

Plant Installation By | : | Vadodara (Ph: 9909922452) |

PMC |

| Anand Institute for Studies in Energy Efficiency & Climate Change (AISECC), MOGAR |

Introduction to 45 m³/day Biogas Plant at Uday Farm, Ramnagar Campus

A 45 cubic meter per day capacity institutional biogas plant is installed at Uday Farm, Ramnagar campus, operated primarily using local cow dung collected from the Gaushala. The plant has been developed by Charuttar Agro. Producers & Processors Pvt. Ltd. (CAPPL), Mogar, and is designed to sustainably treat organic waste and produce clean, renewable biogas for cooking and energy needs on campus.

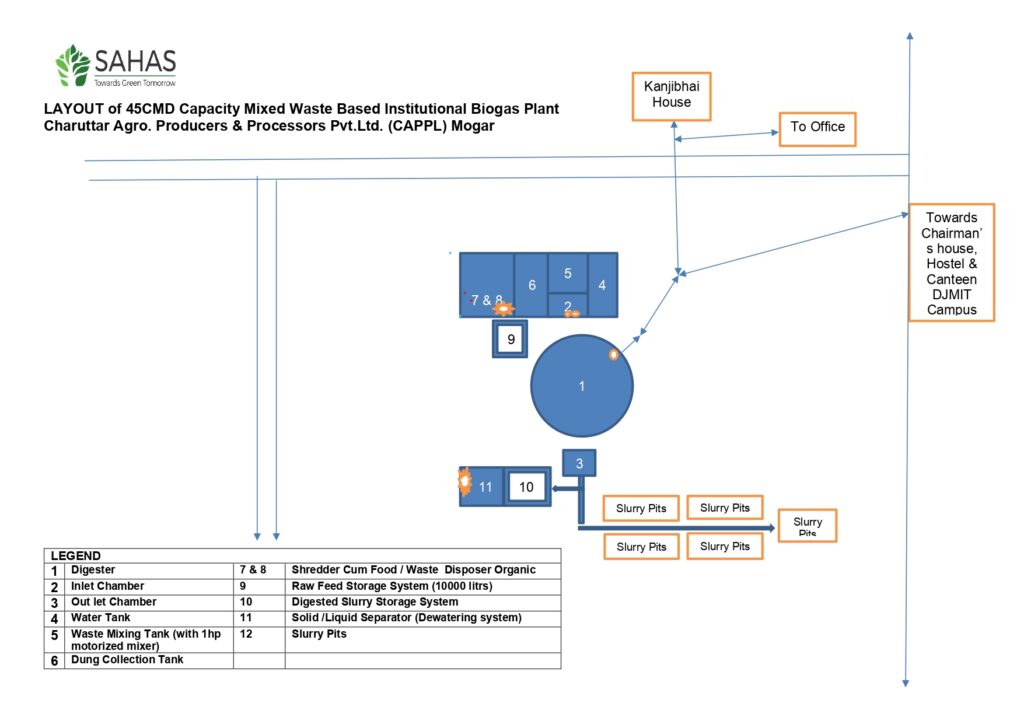

Project Layout

Key Plant Components (as per layout)

- Digester (1): Anaerobic digestion of cow dung and organic waste to generate biogas.

- Inlet Chamber (2): Entry point of mixed slurry into the digester.

- Outlet Chamber (3): Discharge of digested slurry for further processing.

- Water Tank (4): Used for mixing and process needs.

- Waste Mixing Tank (5): Equipped with a 1 HP motorized mixer to ensure homogeneous feed slurry.

- Dung Collection Tank (6): Collects cow dung from the Gaushala before mixing.

- Shredder cum Organic Waste Disposer (7 & 8): For processing kitchen and organic waste before digestion.

- Raw Feed Storage Tank (9): 10,000-liter capacity for storing prepared feedstock.

- Digested Slurry Storage (10): For temporary holding of digested effluent.

- Solid/Liquid Separator (11): Dewatering system to separate manure solids from liquid.

- Slurry Pits (12): Final storage of treated slurry; can be reused as biofertilizer.

♻️ Function and Benefits

- Converts approximately 1.5 to 2 tons of cow dung and organic waste daily into biogas.

- Supplies renewable energy for campus cooking (hostel/canteen) or heating.

- Generates nutrient-rich bio-slurry, which can be reused in agricultural fields.

- Reduces methane emissions from unmanaged dung and waste.

- Promotes sustainable waste management in a rural institutional setting.